Good Quality High Precision CNC Machining Parts of Brass

$5-25 /piece

| Payment Type: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Min. Order: | 1000 piece |

| Port: | Shanghai Ningbo |

$5-25 /piece

| Payment Type: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Min. Order: | 1000 piece |

| Port: | Shanghai Ningbo |

Model: Other

Year: Other

OE NO.: GL18

Car Fitment: Other

Brand Name: Oem

Material: Aluminum.

Grade: A356 A360 AC2C

Heat Treatment: T6 Heat Treatment Continue

Applied Software: Pro/E,Auto CAD

Weight: 0.05kg~20kg

Machining Equipments: Gravity Casting machine -23 Sets.

Surface Finished: Sandblasting, painting, polishing, Powder Coating

Main Products: Intake Manifold.

Service: OEM service available

Place Of Origin: Zhejiang, China

| Selling Units | : | piece |

| Package Type | : | According to customers' orders |

The file is encrypted. Please fill in the following information to continue accessing it

Grade: A356 A360 AC2C

Product weight: From 0.05kg to 20kg

Heat Treatment: T6 Heat Treatment Continue

Surface finished: Sandblasting, painting, polishing,powder coating

Applied software: Pro/E,Auto CAD,Solid Work ,CAXA, UG, CAD/CAM/CAE

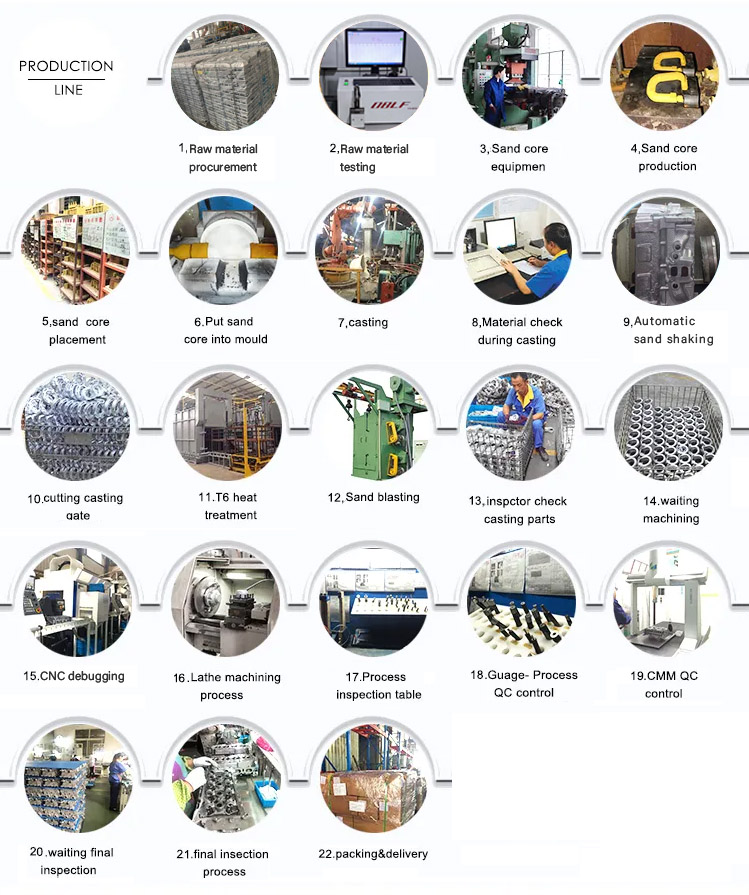

Machining equipments:

Gravity Casting machine -23 Sets

Sand Core machine -15 SetsDrilling machine - 100 sets

Main products:

Intake Manifold series,Cylinder Head series and Pump series

Train spare parts and all kinds of aluminum casting partsThey can be produced according to customers’ designed drawings

Service:OEM service available

Machine Name

Brand & Model No.

Quantity

Condition

Core Shooting Machine

JL6G35

23 4 Acceptable

Pouring Machine

NZJ630Q

15 4 Acceptable

Mechanical Arm

ABB

2 3 Acceptable

Shot Blasting Machine

Q37, Z-PW001

3 7 Acceptable

CNC Lathe

CJK6132

19 6 Acceptable

Machining Center

J-JG001, F500

80 4 Acceptable

Cleaning Machine

ZQZ, J-QX002

5 3 Acceptable

Heat Treating Furnace

HJJX-25

1 1 Acceptable

Drilling Machine

ZS4116

40 6 Acceptable

|  |  |  |

|  |  |  |

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

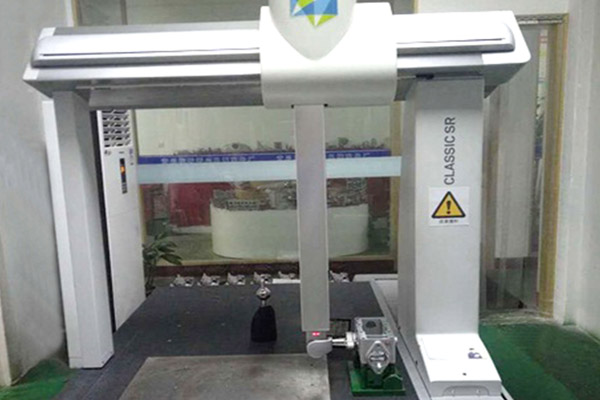

| Coordinate Measuring Machine | 754T-M, HEXAGON | 2 | 3 | Acceptable |

| Spectrum Analyzer | METALSCAN-2500 | 1 | 4 | Acceptable |

| Tool Preseting Measuring Instrument | ET-300H | 1 | 4 | Acceptable |

| Electronic Pull Tester | LDS-W50A | 1 | 5 | Acceptable |

| Sand Intensity Machine | XQY | 1 | 4 | Acceptable |

| Automated Polishers | P-2 | 1 | 4 | Acceptable |

| Hardness T ester | HR-150A | 1 | 4 | Acceptable |

| Torque Wrench Calibrator | Zhunda | 1 | 1 | Acceptable |

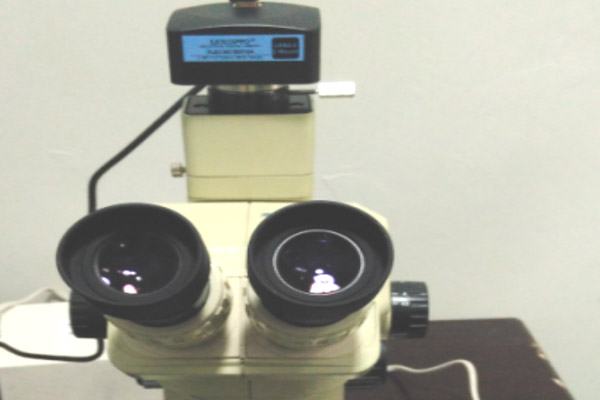

| Metalloscope | ikowan | 1 | 3 | Acceptable |

| Air-Tightness Tester | LS-1863X | 8 | 2 | Acceptable |

|  |  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

A: Our company was founded in 1983, has more than 300 employees and covers an area of 35,000 square meters .

Q2,What is the deliver time ?

A: We need 30-45 days to make the mould, and need more 7-10 days to produce the product.

Q3, How is the quality ?

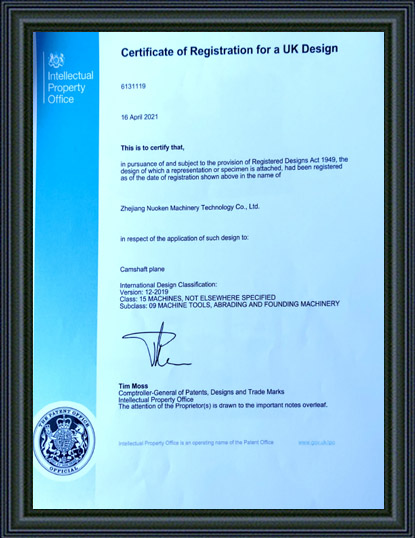

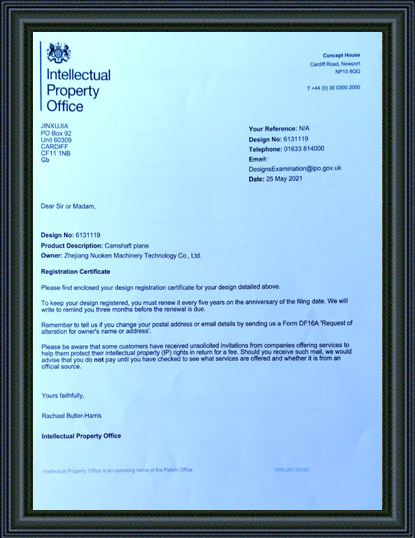

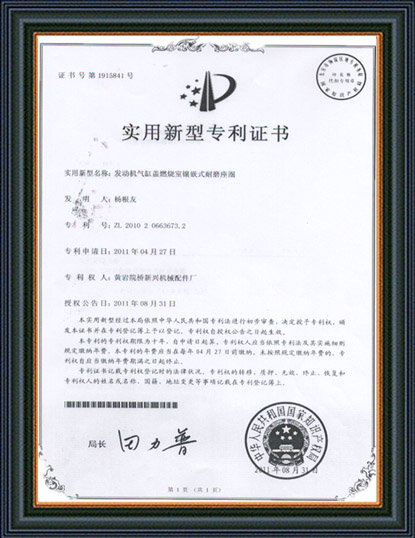

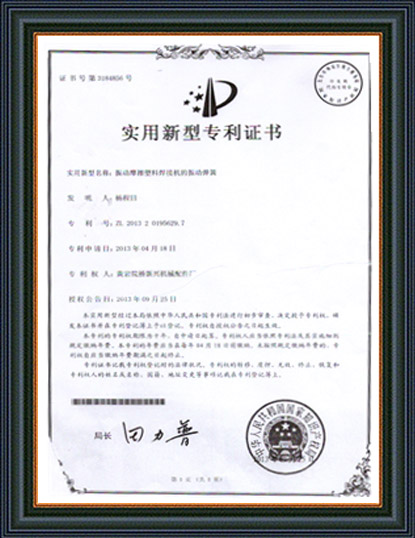

A : We have been cooperating with the domestic OEMS companies all the time. We passed the IATF 16949, AND "Zhongqi Metrology System Center" . And we has established a testing center and 24 hours constant temperature and humidity measuring room.

Q4. Can you help with the delivery of the goods?

A: sure, we can help goods through our customer freight or our freight forwarders.

Q5: Can you provide samples for free ?

A: It depends on the cost of the sample.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.